Happy New Year to all ~

In the past week, I removed all of the left-over painter's tape from the painting project, and hung up some current and previous train calendars. We entertained the Mize's on Friday, and they got to see the two train setups in action. I placed a second (and final) tub's worth of train literature in an antique trunk for display, and put away my various Christmas train goodies.

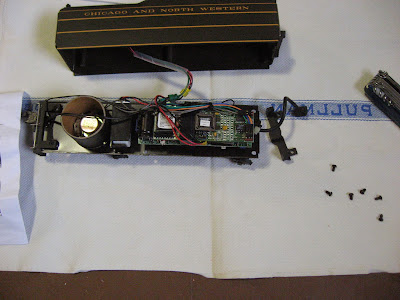

Over the weekend, I used the ProtoSounds reset chip my wife got me for Christmas to perform some surgery on my MTH Chicago and Northwestern E4 Hudson. If a ProtoSounds 1.0 locomotive sits for too long without being run, the sound system may need to be reset. When powering up the engine, it will sound 3 "clanks", signifying that a reset is required. The engine will not run at all when a reset is required. Well, that has been the case for several years for the E4, and thanks to my wife, I've finally been able to do something about it! To start the process, I placed the engine on a powered track for 2 hours to charge the on-board battery. Then, I removed the cover on the tender. I placed the tender and its various components on an authentic Pullman towel to protect them (and prevent them from rolling away.) Using a special tool, I removed the ProtoSounds computer chip and replaced it with the reset chip. I put the cover-less tender back on the track, and re-tethered it to the locomotive, and applied power. It played the appropriate sound file, advising that the system was successfully reset. I then removed the reset chip and placed the ProtoSounds chip back. I then re-tethered the tender to the engine, and tested it - it successfully cycled from forward to neutral to reverse and back to neutral! I also discovered that the on-board battery required replacement, so I addressed that issue as well. After reassembling the tender, I found that the cable tie that holds the tether in place was outside of the tender rather than inside, so I had to disassemble the tender again, and placed the cable tie at the right spot. After putting it back together (the entire surgery was performed with my Swiss Army CyberTool 34), I hooked the locomotive up to the waiting freight (using the ProtoCoupler gimmick), and the unequaled flagship of my O-Scale fleet flew down the track once again . I reactivated the smoke unit (it had been turned off while charging the engine for 2 hours), and it performed well with a full head of steam! I noted that the "chuffing" sound of the locomotive was not working, so I performed a reset using option 18. That fixed the "chuffing" issue, and now it provides a more authentic sound. The whole procedure took about 35 minutes. Thank you again to my bride for helping to bring about the triumphant return of the mighty E4 Hudson.

On Monday night I gathered several tubs of office supplies into the Train Room and began sorting them. Amber helped finish up this quick project on New Years Day. Our office supplies are now easily accessible and sorted (and labeled), and the Train Room is now ready to be visited again!

|

| The E4 Hudson was charged on the tracks for about 2 hours before surgery |

|

| The tender cover has been removed, exposing the internal electronics |

|

| Now the ProtoSounds chip has been removed. The reset chip was installed and run successfully, and then all of the components were reattached |

|

| The C&NW Hudson pulls a freight for the first time in years |

|

| I tested the engine's functionality and refreshed my understanding of its various sound tricks |

No comments:

Post a Comment